Working with the client

Brodeen Engineering was awarded a major mechanical contract to provide the utilities and product services to a large dairy processor's new spray dryer facility, in Tipperary.

The team here at Brodeen Engineering are proud to support our local community, so we were delighted to work with the client, who has been supporting employment in Tipperary for over 100 years.

The Job

Through previous work with the client, we developed a reliable reputation and were awarded a main engineering contract with the company.

For this contract, a number of our service offerings were required, including:

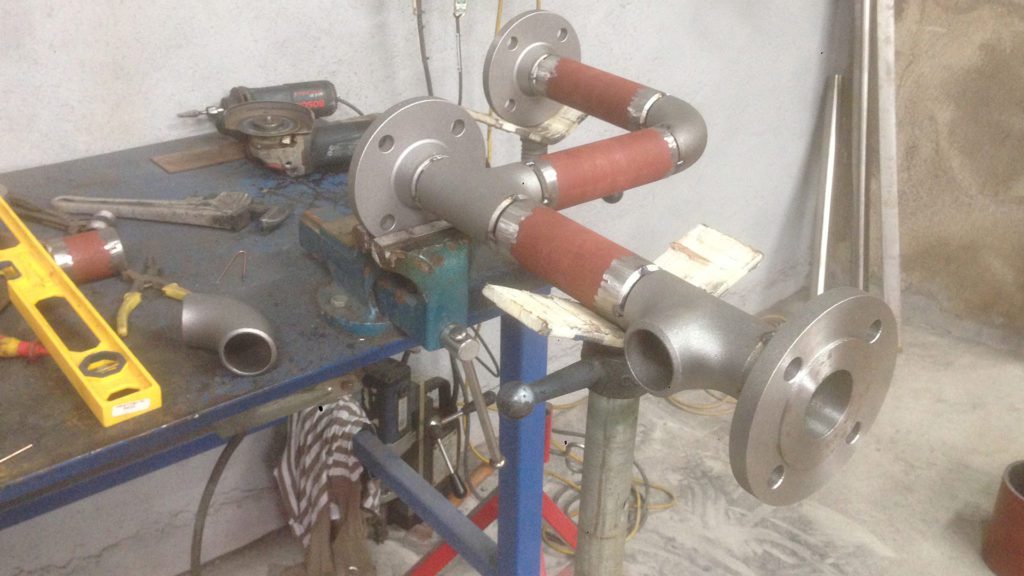

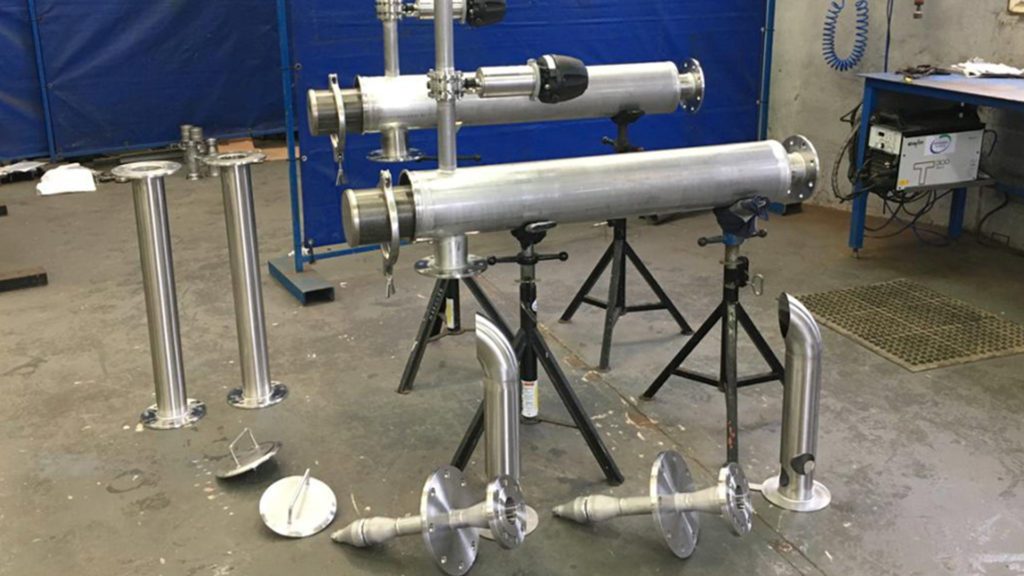

- Pipe Fabrication and steel installation

- Valve and skid module procurement

- Insulation of pipeworks

- Pressure testing and commissioning

The main body of the contract involved the fabrication and installation of utility services to its newly built second dryer facility, which was comprised of both carbon steel and stainless steel pipework.

Our process

Pipe fabrication and NDT were completed off-site at our dedicated workshop just outside Tipperary Town. This allowed us to mitigate the number of hours our team spent on-site, lowering the associated risks for our client and minimising on-site disruption.

Next, our skilled and safety-conscious team moved on-site to deliver, install and pressure test our pipes.

For this project, we also handled the procurement and installation of valves, as well as submittals for a Firewater skid unit.

Finishing touches

Once the pipework was pressure tested and received the client's sign-off, we then fitted insulation and cladding for all of the pipework.

Minimal disruption

Due to the high intensity of the facility, pipework tie-ins were coordinated and completed around plant production, with most work taking place at off-peak hours.

Due to our excellent track record in delivering to tight deadlines in live facility conditions, the client trusted our team to deliver under these restrictive conditions.

The Results

This lucrative contract was won on the back of Brodeen Engineering’s top-class track record and trustworthiness. Our emergency back-up assistance and on-call breakdown service inspired confidence in the client.

At Brodeen Engineering, we pride ourselves on producing the best outcomes for our clients. Completing work from our state-of-the-art workshop mitigates on-site hours, prevents delays, reduces risks and enables our team to deliver on schedule.